Promote The Upgrading Of New Products Across The Board

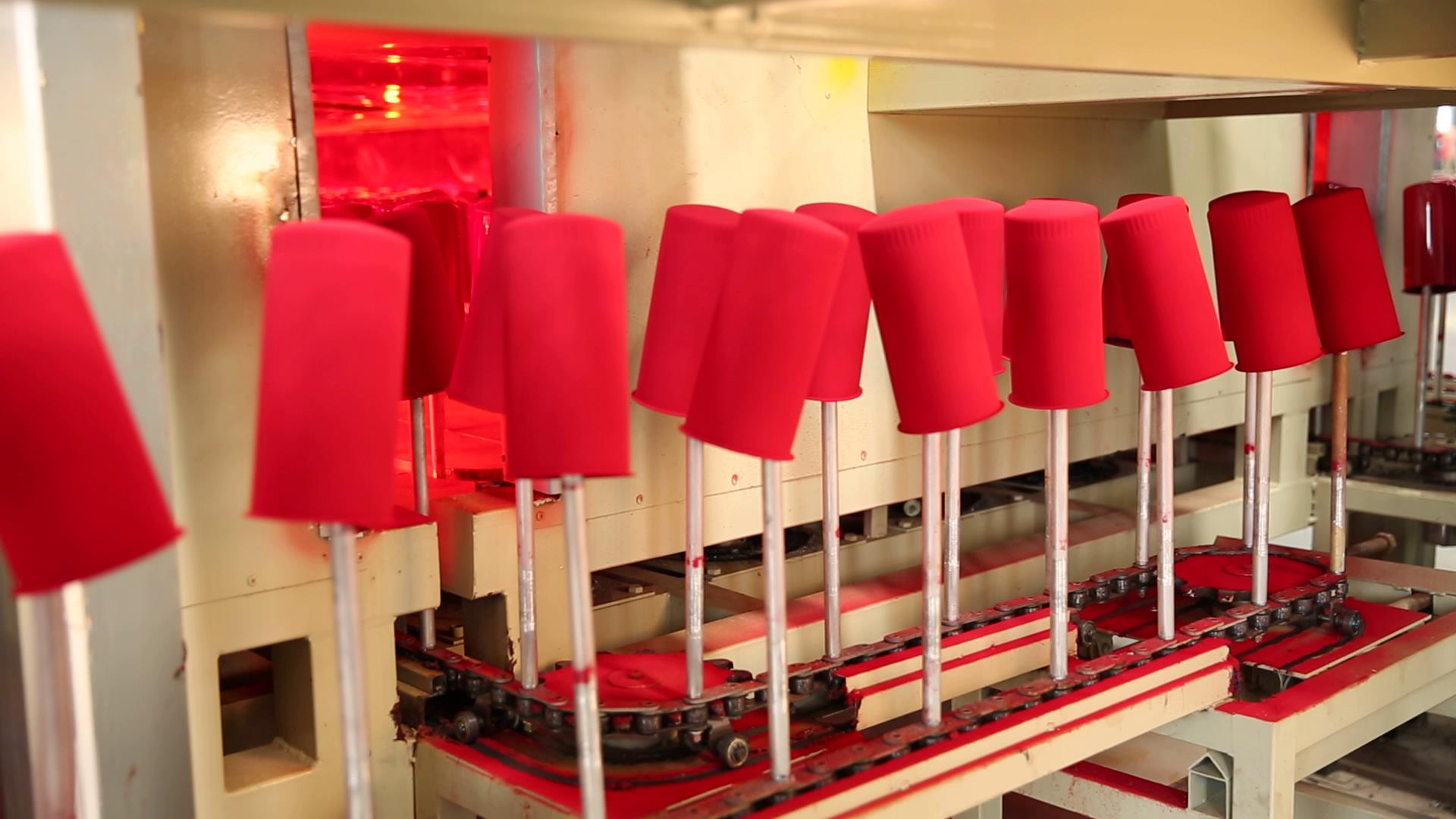

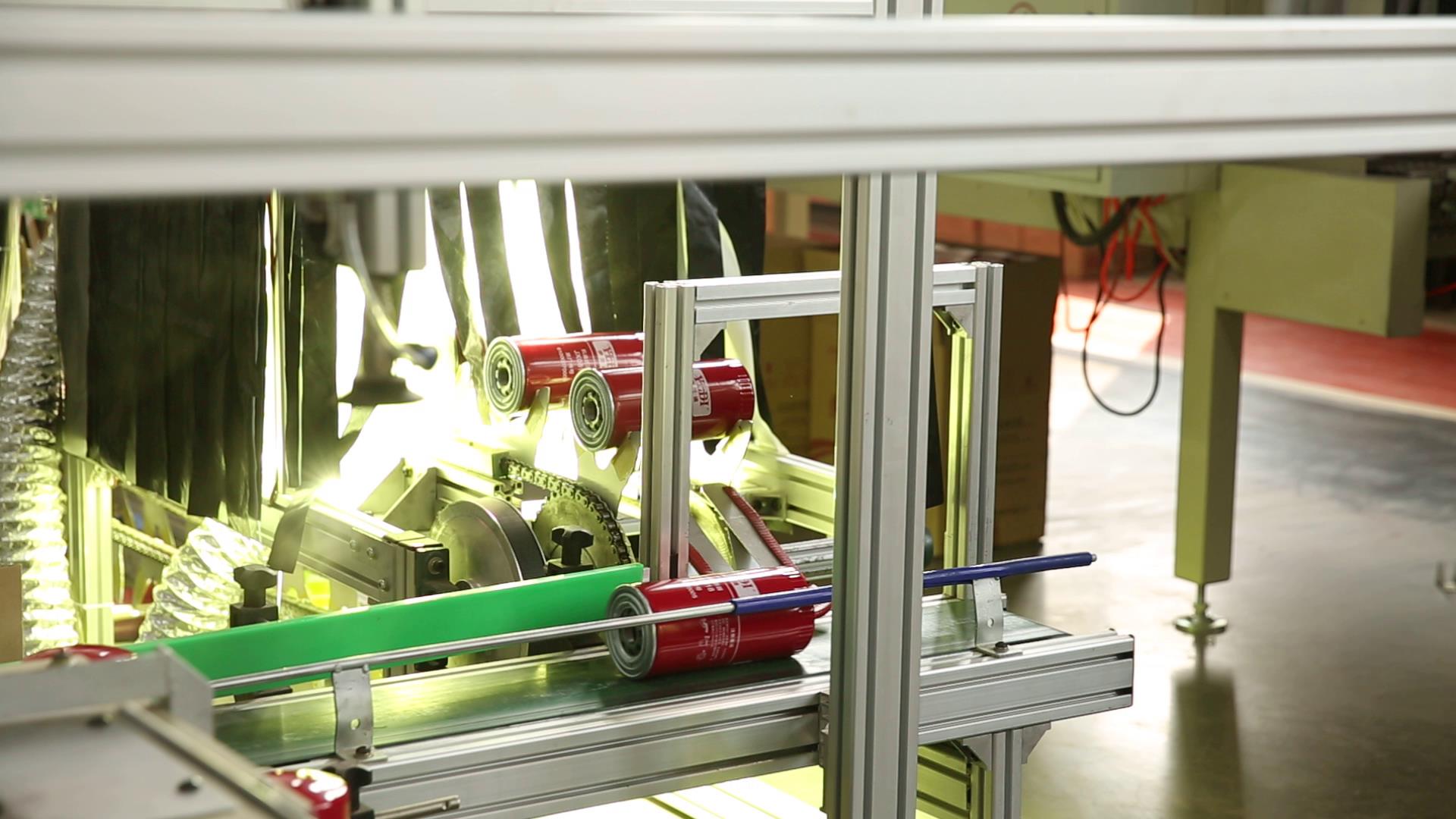

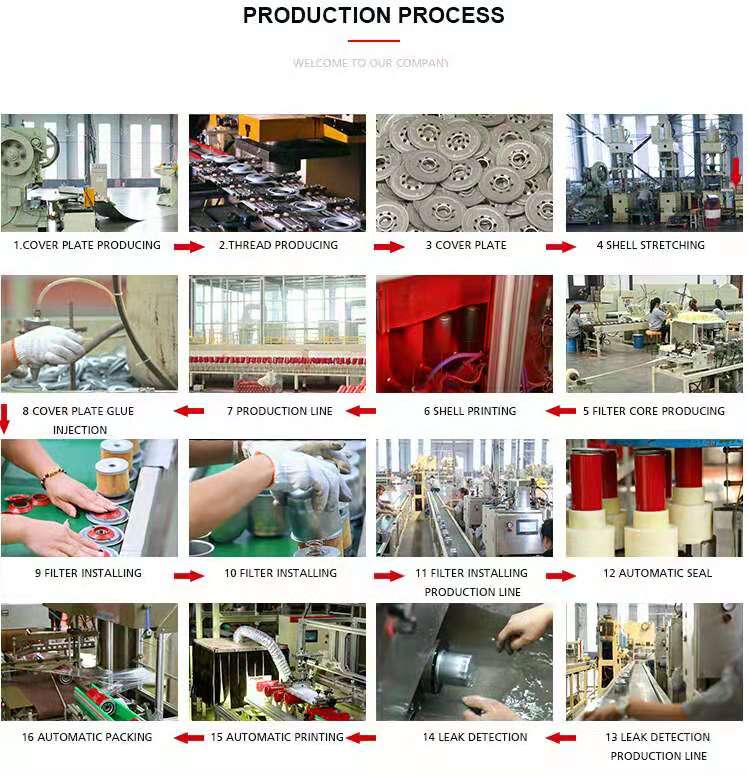

In order to expand the company's scale and increase production capacity, the new plant of decos has been completed. The new area is located in the automobile industrial park of Qinghe County, Hebei Province, China, and in the automobile and motorcycle industry gathering area of Xiangjiang street and Wuzhishan road. The new plant covers an area of 100 mu and a construction area of 53000 square meters. The new production line is mainly used for the stamping and stretching of rotary oil filter, air filter and products. The new plant area consists of raw material warehouse, finished product warehouse, laboratory, air filter workshop, oil filter workshop and office area. In terms of management, decos also introduced the Toyota TPS lean management mode, which greatly improved the production quality and work efficiency.

The new factory has eight new stamping lines, of which the screw plate stamping line and dense plate stamping line adopt the current advanced technology in the industry, realizing automatic feeding, automatic discharge and abnormal automatic line stop alarm, so as to meet the stamping production of high-precision materials. It has a high degree of consistency in ensuring product quality, greatly reducing the unqualified rate, saving raw materials by 30% and improving safety performance by 100% compared with traditional equipment. The shell drawing line also realizes automatic and standardized production synchronously. Thanks to the upgrading of the equipment, the raw materials are saved by 30%, the safety performance is improved by 100%, and the production efficiency is also improved by 30%.

The new factory has eight new stamping lines, of which the screw plate stamping line and dense plate stamping line adopt the current advanced technology in the industry, realizing automatic feeding, automatic discharge and abnormal automatic line stop alarm, so as to meet the stamping production of high-precision materials. It has a high degree of consistency in ensuring product quality, greatly reducing the unqualified rate, saving raw materials by 30% and improving safety performance by 100% compared with traditional equipment. The shell drawing line also realizes automatic and standardized production synchronously. Thanks to the upgrading of the equipment, the raw materials are saved by 30%, the safety performance is improved by 100%, and the production efficiency is also improved by 30%.